Testing Laboratories: Strategies for Exact Results

Wiki Article

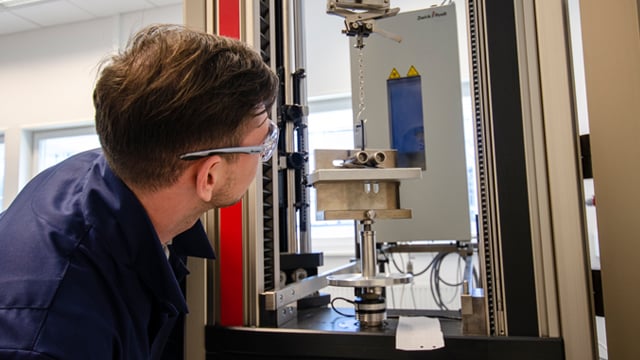

Quality Guarantee Laboratory: Guaranteeing Material Integrity

Are you interested concerning how a Top quality Assurance Laboratory makes certain product stability? In this short article, we'll take you behind the scenes of a lab that makes sure the high quality of products.Evaluating Procedures

Equipment Calibration

See to it to frequently calibrate your equipment to keep accuracy and accuracy in your dimensions. Equipment calibration is an important element of quality control in the lab. By calibrating your instruments, you make certain that they are offering accurate as well as reliable data, which is vital for making informed choices regarding the stability of materials being tested.

Calibration involves contrasting the dimensions of a gadget to a well-known requirement. This procedure helps recognize any kind of inconsistencies or mistakes in the instrument's readings. Routine calibration makes sure that your devices continues to be in ideal condition, guaranteeing that your dimensions are consistently exact.

Furthermore, keeping a record of calibration tasks is crucial. This documentation enables you to track the efficiency of your instruments gradually and also supplies evidence of compliance with quality assurance criteria.

Sample Preparation

When preparing examples, it is very important to comply with a standard treatment to make certain uniformity as well as accuracy in your measurements. Beginning by carefully selecting the appropriate sample size and ensuring it accurately represents the larger set. Usage clean and calibrated tools to avoid contamination as well as maintain precision. Begin by thoroughly blending the product to assure homogeneity. This action is important as it ensures that the sample you take is rep of the whole set. Next, carefully part the example into the required containers, making certain that each container obtains an equivalent quantity. This assures that each measurement is precise and also reflective of the entire set. Make sure to identify each container appropriately, noting any type of appropriate my site information such as date, batch number, as well as example type. Finally, store the samples correctly to preserve their integrity up until screening. Follow the designated storage guidelines, such as temperature and also humidity demands, to preserve the samples' characteristics. By sticking to these standardized procedures, you can make certain that your dimensions are regular as well as precise, giving trusted data for quality control objectives.Paperwork and also Record-keeping

To maintain exact records, it is very important to thoroughly record pertinent information such as batch number, example kind, and also day. When working in a quality control laboratory, documentation as well as record-keeping are important aspects of your job. By thoroughly videotaping all the required information, you ensure that there is a clear trail of information that can be conveniently accessed and referenced when needed.When recording batch numbers, it's necessary to consist of the distinct identifier assigned per set. This assists in tracking the origin and also background of the product being tested. Additionally, noting the example kind is crucial as it gives context and also permits for exact classification and also evaluation of the information. Finally, recording the day is critical as it assists in tracking the timeline of events and ensures that results are correctly aligned with the matching sample.

In regards to record-keeping, it is very important to establish a systematic strategy. This includes developing a standardized style for documenting details, arranging documents in a sensible manner, and also guaranteeing regular back-ups to avoid information loss. By following these methods, you add to the overall efficiency and honesty of the laboratory's procedures.

Continual Enhancement

As you learn the facts here now aim for continual improvement, bear in mind that little modifications can bring about significant innovations in performance and also productivity (testing laboratories). In a high quality guarantee lab, it is important to frequently examine and improve your procedures to make sure the highest degree of material stability. By making small changes to your testing methods, paperwork procedures, as well as tools calibration, you can enhance the accuracy and also integrity of your outcomesOne method to achieve continual improvement is by frequently assessing your common operating procedures. Recognize any areas that can be structured or streamlined to conserve time and also lower errors. Carrying out far better training programs can additionally add to improving effectiveness and also performance. By offering your team with the required abilities as well as expertise, you can guarantee that they perform their tasks successfully as well as with confidence.

An additional facet of continuous renovation involves leveraging innovation. Check out the current innovations in lab tools as well as software program to automate recurring jobs, enhance data browse around here analysis, and boost general efficiency. Embracing brand-new technologies can bring about time savings and also boosted accuracy in your screening procedures.

Promoting a culture of continuous renovation within your group is important. Encourage open communication and responses, allowing every person to add their suggestions as well as ideas. By encouraging your team to take possession of their work and also make every effort for excellence, you can develop an atmosphere where continual enhancement becomes a shared objective.

Conclusion

There you have it-- the importance of a quality assurance laboratory in making certain product honesty. With all these steps in area, the top quality assurance laboratory is an important element in guaranteeing the quality and integrity of products utilized in various markets.Report this wiki page